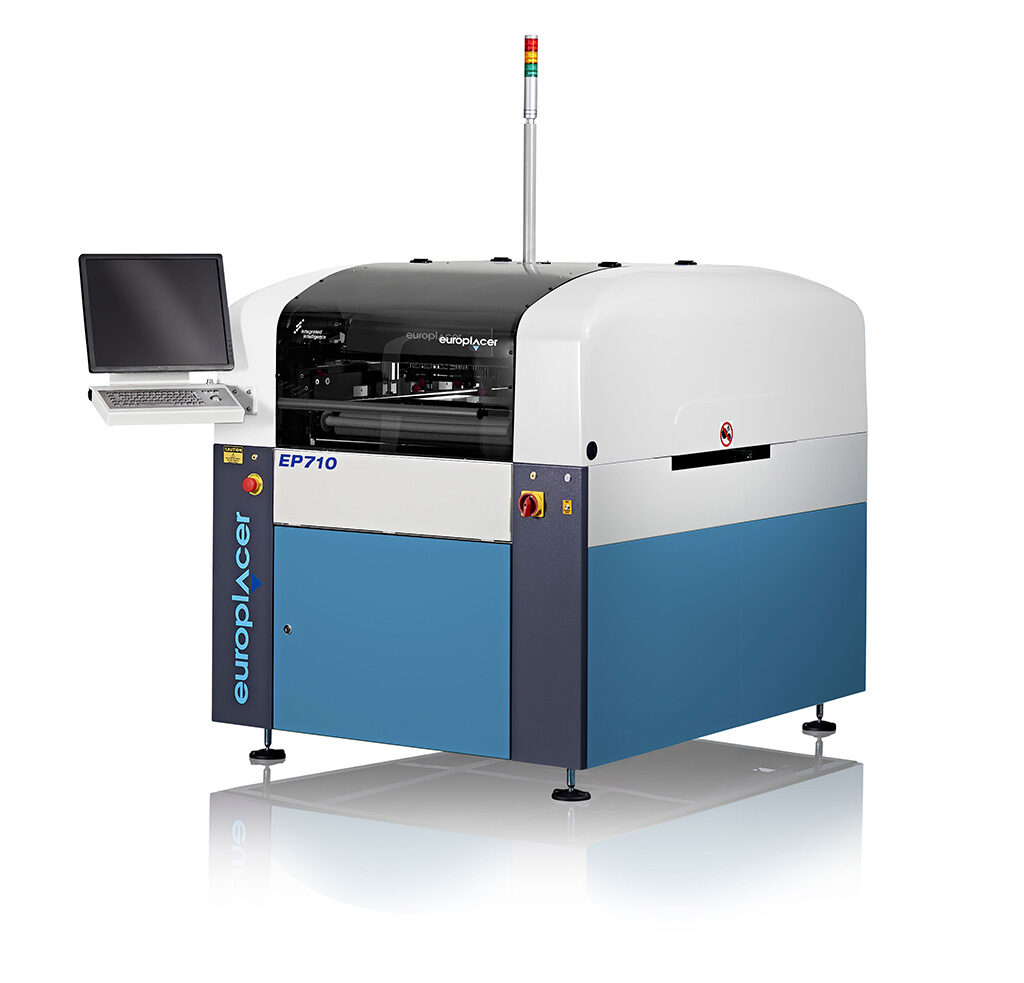

EP710

Europlacer’s ep700 series printers combine the company’s commitment to high performance and reliability with outstanding value. The platform has been developed to cope with the rigors of high volume SMT production. Yet it incorporates the flexibility needed to deliver the fast set-up and product changeovers demanded by low and medium volume operations working in high-mix environments.

Designed with ease of use, high-end performance and low cost of ownership in mind, the platform utilises the most advanced drive control technology available, including 1 micron resolution linear encoders on all axes. A suite of intuitive software enables total control of the printing process.

The printers are fully equipped, as standard, with many features such as automatic rail width adjust, auto stencil loading, a fully programmable Under Stencil Cleaner and even automatic stencil paste inspection. In fact, everything you need to complete the SMT print process without exception or compromise.

The vision system utilises a unique Dual Roving camera (DRc) method for automatic board and stencil alignment. Not only does this innovative vision system provide the highest level of alignment capability, it also incorporates SmartCal.

With the ongoing minaturisation of substrates and components continuously reducing the process window, SmartCal provides the user with immediate and cost-free calibration. SmartCal allows maximum process window and optimum performance to be maintained for the operational life of the machine. The ep700 series also deploys a unique capability to check for solder paste presence on the stencil before printing. The vision system aligns the PCB with the stencil using fiducial marks or PCB & stencil features.

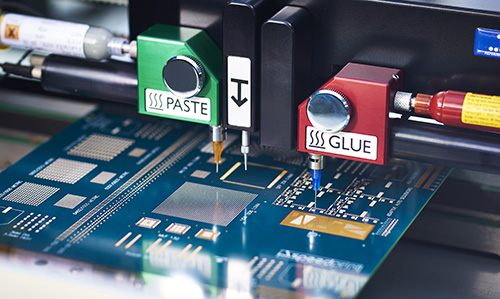

The ep710 printer incorporates the ADu or ADu+ option, giving it the unique capability to dispense a wide range of media such as paste, glue or flux through removable temperature controlled modules that contain precision machined Archimedes augers. Programming is simply drag ’n’ drop using our Gerber import tool. It allows full customisation including the deposition of lines onto any substrate.

A range of production and process options are available across the ep700 series, allowing you to implement additional efficiencies and controls within your printing process.

The PCB transport system includes a fully programmable board stop and employs pneumatically controlled foil PCB clamping. The system is SMEMA compatible to ease integration with fully automated SMT production lines.