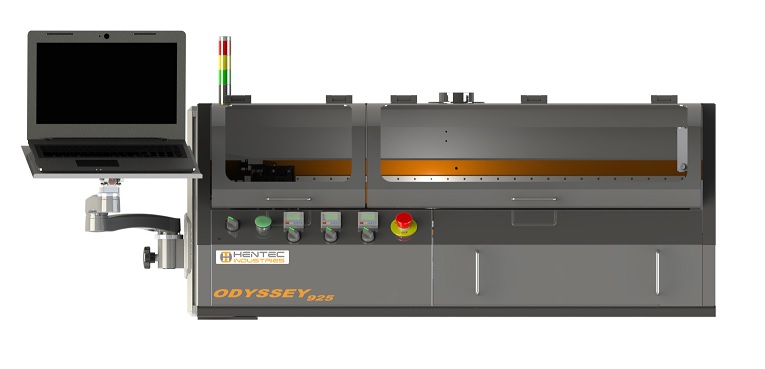

The Odyssey 925 is a mid-range lead tinning machine for electronic component tinning and re-tinning applications. It is capable of production volume processing, and efficiently priced and sized. The Odyssey 925 lead tinning system can be configured with 4 possible stations, including a 35-lb solder pot for scavenge, a flux station, a preheat station and a dynamic solder pot for high precision tinning application. Optional rotation is available to handle QFPs and other multi-sided components.

- High Volume, High Mix Capacity

- Unlimited Programs

- Auto Load/Unload

- Mil Spec Compliant

- Interpolated X and Z Rotation Motion Control

- High Precision Ball Screw Motion

- Wide Process Control:

solder temp, emersion depth, travel speed, dwell time, simultaneous moves

- Unlimited Programs | Integrated Laptop for Programming and Operation

- High Precision Lead Screw Motion | Repeatability ± .002″

- Interpolated X, Z, Rotation Motion for Superior Solder Performance

- Wide Process Control: solder temp, emersion depth, travel speed, dwell time, simultaneous moves

- Agitation Motion for Effective Alloy Removal

- Automated Rotation for QFP Processing (option)

A high volume lead tinning machine for electronic component tinning and re-tinning applications, the Odyssey can strip, flux, condition, tin, or re-tin virtually any component. The Odyssey is a made-to-order system consisting of 6 configurable 5 x 8” stations. Options include pre-heat, rinse, dry, and secondary flux. Standard and Custom tooling are available for the Odyssey, as well as single and multiple rotation tooling (for Flatpack and QFP’s).

- High Volume, High Mix Capacity

- Unlimited Programs

- Auto Load/Unload

- Mil Spec Compliant

- Interpolated X and Z Rotation Motion Control

- High Precision Ball Screw Motion

- Wide Process Control:

solder temp, emersion depth, travel speed, dwell time, simultaneous moves

The Odyssey can be configured with 3 additional stations, which can include auto load/unload, rinse, 2nd flux, preheat, or dry stations (the preheat and dry stations can be combined into one station). The extensive configuration capabilities of an Odyssey enable durable and lustrous solder coating of a wide array of common and exotic through-hole and SMT components including QFP, QFN, SOT, axial, discrete, BGA, PLCC, CLCC, DIP, SIP, capacitor, resistor, and inductor types. Rotation, tilt and custom dip nozzles can be deployed to handle multi-sided and fine pitch applications.