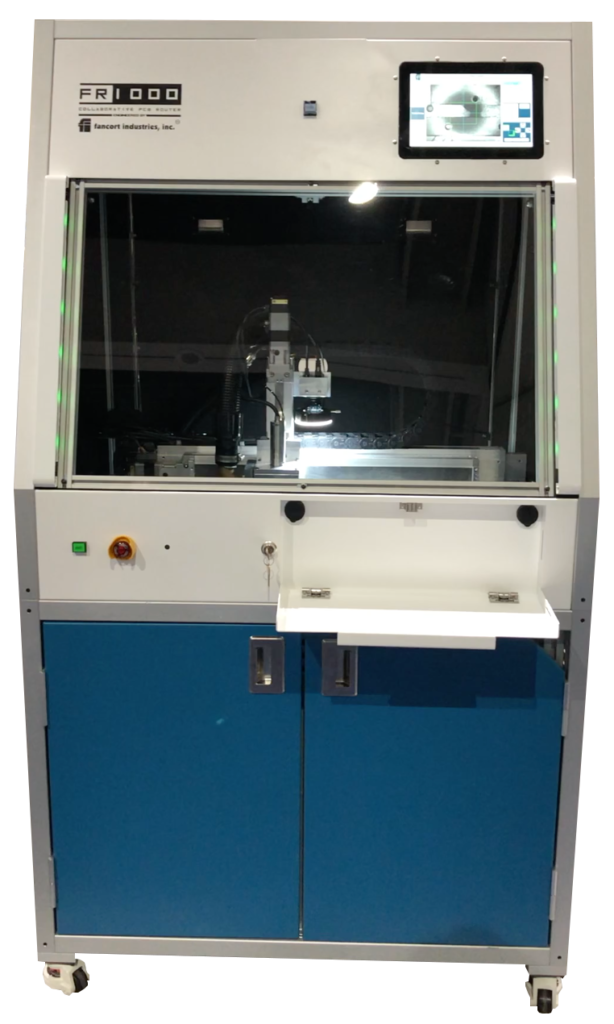

Introducing Fancort´s FR-1000 stand alone collaborative ready PCB router machine, specially designed as a low cost solution to meet medium volume PCB depaneling requirements with a machine that provides the mechanical properties necessary for reliable accurate depaneling.

FR-1000 PC Board Router

Universal or Dedicated Fixtures with Fiducial Recognition

The FR-1000 is capable of depaneling boards up to 457 mm x 355 mm and up to 3 mm thick, single working area machine with top vac dust removal system, and 350 watt high speed spindle.

- Large panel size: 457 mm x 355mm.

- Powerful gantry system.

- Easy vision jog and teach programming.

- Small overall footprint.

- Vac filtering for ultra clean operation.

- Fiducial mark vision alignment.

- Vision based bar code and pattern recognition program selection.

- Manufactured in the USA/NJ by Fancort Industries, backed with one year warranty.

- Quick release for fast bit changeover.

- Fixture comes standard equipped as a universal fixture but can also easily accept dedicated tooling for fast change over for mixed environments.