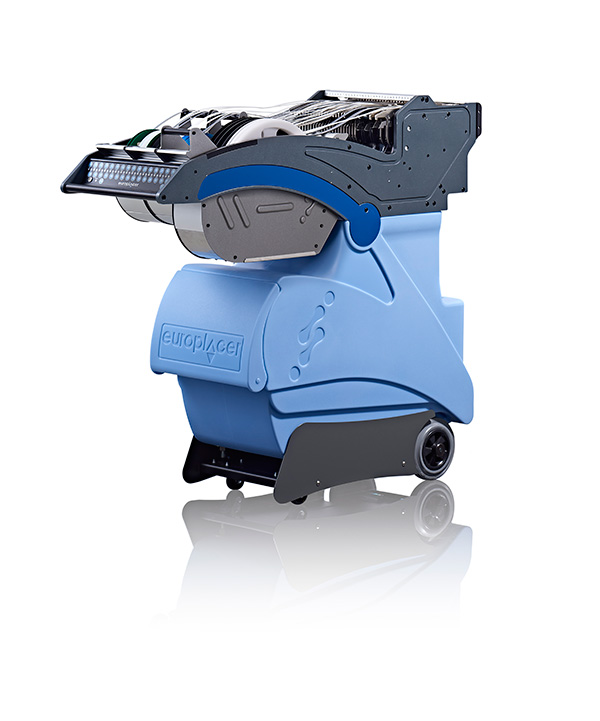

In reality, iineo+ is never having to say “no”…just one machine with no limits.

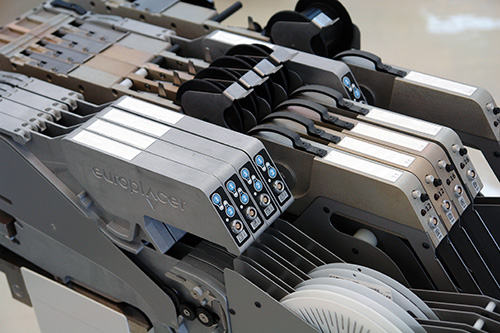

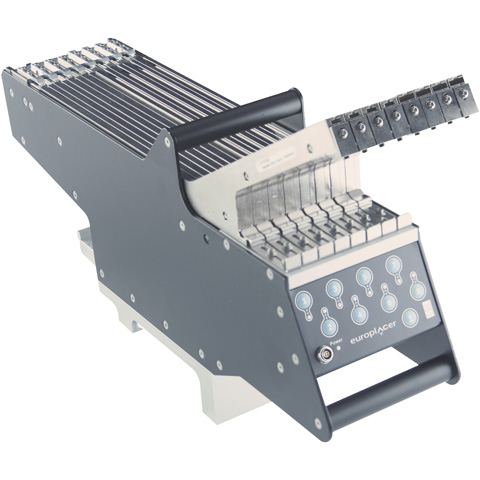

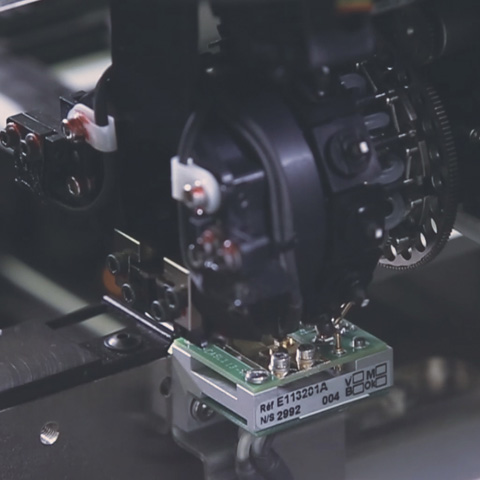

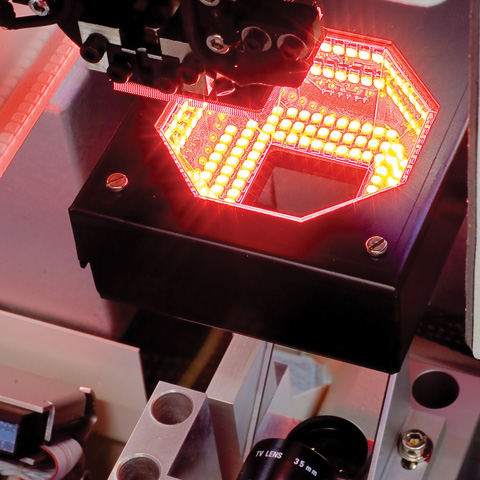

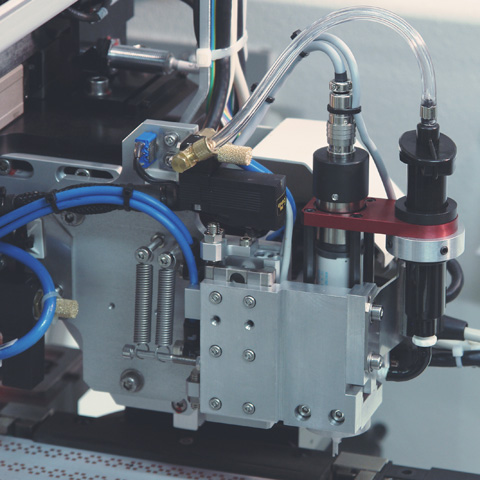

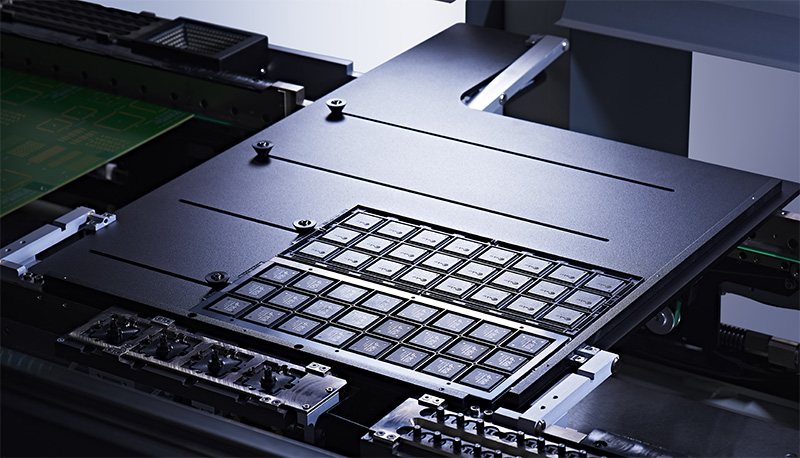

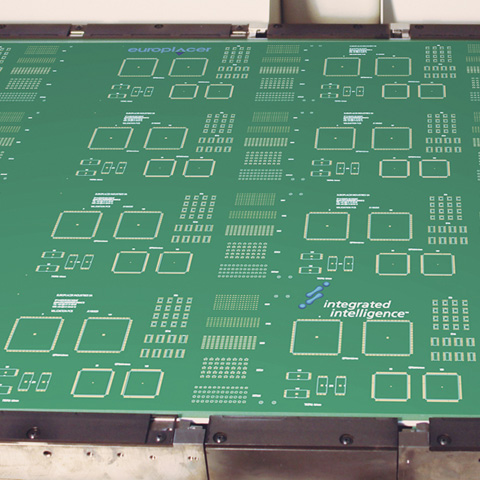

Fitted with linear motors and digital cameras, the pick and place iineo+ platform also utilizes Europlacer’s unique and proven core features such as Integrated IntelligenceTM , intelligent feeders, smart nozzles and 3DPS providing guaranteed closed loop control of pick and placement forces for all components. In addition, if you need to produce very large boards and the standard configuration is not enough, iineo+ is capable of being configured to manage 1610mm x 600mm size substrates too.

iineo+ I

Technically speaking, iineo+ is a multi function SMT Pick and Place platform , with the highest level of flexibility and feeder count in the industry. It is widely configurable without the need to compromise on feeder count, placement speed or component capability.

- PCB sizes from 60mm x 60mm up to 1610mm x 460mm

- rotary turret heads with 8 or 12 placement nozzles

- feeder positions – 264 x 8mm

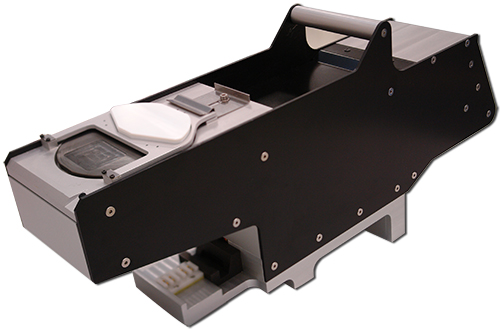

- Jedec storage positions – up to 10 internal trays

- component size – 01005 to 99mm x 99mm

- component weight & height – 300g and 34mm

- component testing capability – with independently verifiable calibration (UKAS / NIST / PTB… etc.)

- dispensing – archemedes or air/time for glue or solder paste

- every nozzle position can place all and any component types, for real line balancing and no limitations

- odd form & smart nozzle banks

The pick and place iineo+ I features a single rotary head on the X/Y gantry and contains 8 or 12 ‘Smart’ nozzles, with a maximum placement rate of 15,390 cph (IPC: 12,550 cph)

Click an image below to visit iineo+I options