Feeder Options

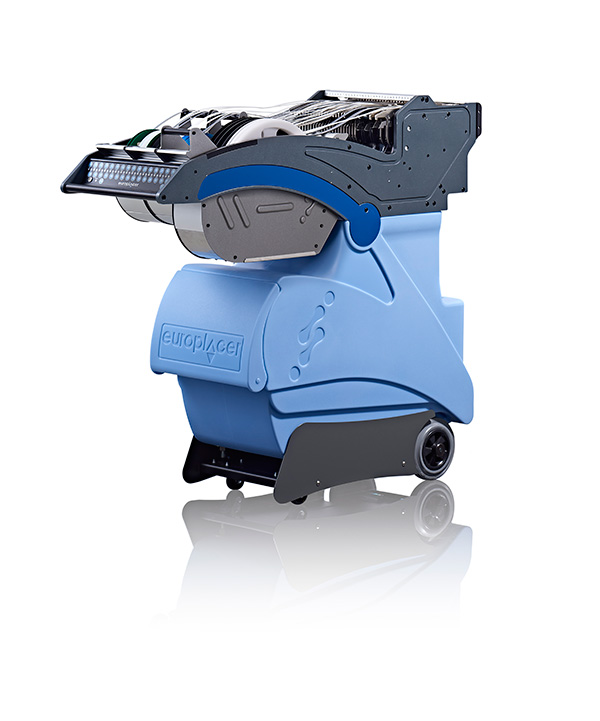

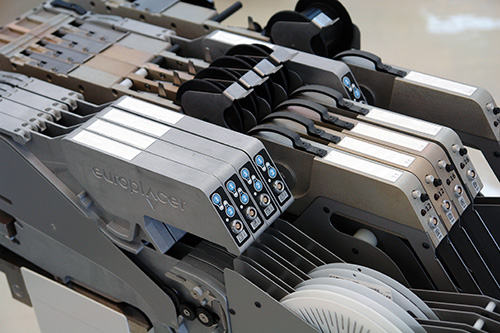

Feeder Cart

Any combination of feeders can be located side by side within the cart, and carts then easily rolled up to and into any position within all Europlacer placement platforms.

- allows fast changeover of feeders

- up to 16 NT feedeer 2x8mm (32 reels 8mm)

- any mix of NT tape, sticks, special feeder

- can be swapped with ii-feed cart or tray loader in seconds

The feeder cart or feeder trolley is mobile which facilitates the block-handling of tape feeders, stick-feeders and special feeders. As part of Europlacer’s Integrated Intelligence system, when connected outside the machine, it provides component fully integrated program and stock preparation. An open-top drawer located in its base collects used tapes or empty sticks from the feeders, giving operators simplicity in use.

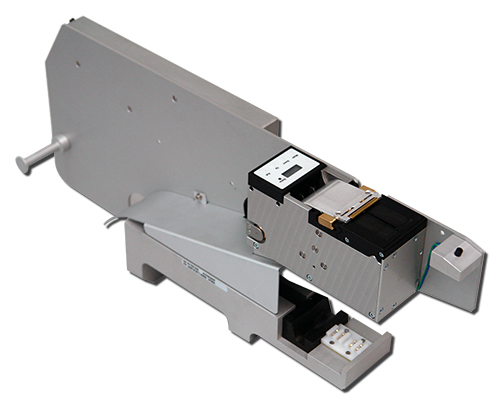

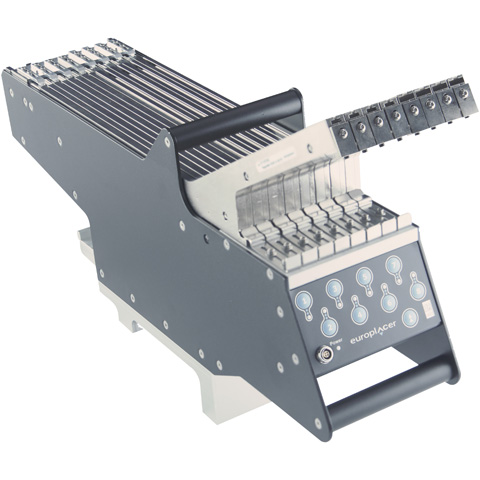

ii-feed

ii-Feed is based on the strengths of Europlacer’s proven concept of a cart plus elements but incorporates key aspects of our individual feeder technology, merging the best of both technologies.

ii-feed cart

- Up to 33 reels 8mm

- Ready for 01005

- Accepts any mix of 8, 12, 16 or 24mm tapes

ii-feed elements

- Each individual element is fully intelligent

- Spool is eliminated, cover lay film is evacuated below the element

- Can be placed at any trolley location, without stopping production, guaranteeing that the correct loading plan is used

- Only one element type for all 8mm tapes, paper, plastic.

intelligent feeder magazines ii-feed ii-feed magazines

- Reels can be prepared offline in magazines for up to 11 references

- Two types are available: 180 mm reels and 330 up to 390 mm reels

- The ii-Feed Cart can accommodate three magazines

Each individual ii-Feed element is fully intelligent, providing the same intuitiveness as the other feeders in the Europlacer range that make the most of our integrated intelligence platform. With the full range of element sizes available, there are no limits to ii-Feed capabilities.

Feeder inventory investment and production complexity is kept to a minimum. There’s no need to worry about how many and which type of 8mm element you may need, as our 8mm elements have no restrictions and will handle any and all your 8mm tapes.

Maintaining our philosophy of investment protection, the ii-Feed system is fully compatible across previous Europlacer machine generations. You can even use them alongside previous generations of Europlacer’s tape trolleys on the same machine – and at the same time.

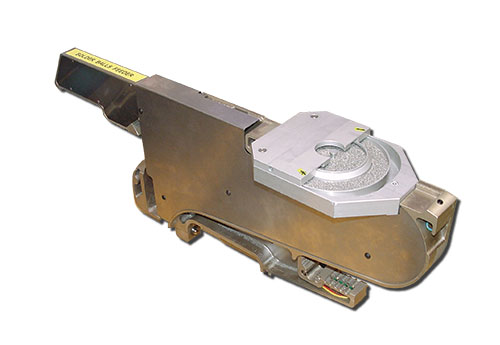

NT feeders

Europlacer developed the world’s first intelligent SMT feeders back in 1993, and the philosophy continues as a thread throughout our product platform.

SMT Intelligent Feeder 2x8mm

- Handle all tapes no matter plastic or paper

- Fed components down to 01005 chips

SMT Intelligent Feeder Single

- Handle all tapes no matter plastic or paper

- Feeder available for tapes between12mm and 104mm

Our SMT intelligent feeders store data about the component type loaded and communicate with the machine to maximise placement efficiency and avoid faulty configuration. Capable of being programmed and replenished off-line, the feeders can be loaded at any time into any position on the machine whilst it is running. The machine will automatically recognise and optimise the production routing to accommodate the feeder.

If a program requires more component types than can be loaded on the machine during initial set-up, additional components can be prepared and introduced individually or by changing a complete feeder trolley.

They can be placed anywhere on the machines, there are no dedicated slots, allowing a first time right loading plan.

Each feeder is equipped with an indicator lamp to facilitate machine control, fault finding and to indicate various states of activity. The feeder can be programmed off line via a hand held micro-terminal that can read 1D and 2D bar codes, through the offline programming station software, or directly by the machine interface.

Fast and accurate calibration of the pick up position is achieved through an individual fiducial mark being present on the feeder, which is recorded when the feeder is loaded into the machine. Accuracy and flexibility of the feeder system provides a huge range of tape sizes from 8mm to 104mm and the capability to reliably place 01005 devices.

Special Feeders

For those extra special applications, Europlacer has developed special feeders for non-standard SMT components that still need to be placed automatically.

Our heritage is solving complex and challenging placement automation issues. Extending the utilisation of your placement platform extends the benefits in throughput and quality. From bulk loose bowl feeders to fluxers and label printers, Europlacer is able to provide an intelligent solution that integrates fully into our standard platforms to meet the most demanding applications.

Stick feeder

Europlacer’s programmable stick feeder is the most flexible solution for components supplied in stick format.

Intelligent Belt Feeder

- Component recognition

- Data entry by micro-terminal and bar code

- Auto adjustment of pick-up offset

- Batch ID for traceability reports

- Fast product changeover

It accommodates SO, SO medium, SO large and TSSOP type components on a base plate capable of handling feeder sticks in eight positions. Different types of SO can fit on the same base, while replenishing the feeders can be completed without halting the machine.

Unlike old vibratory systems with their erratic performance and need for constant adjustment, today’s components are driven on individual belts that almost match the speed of picking from tape feeders. Adaptors are available for most standard SMT components, and special adaptors can be developed for specific applications.

Our Belt Feeder for sticks joins our feeder solutions in being fully intelligent with the same benefits and features as the other feeders in the Europlacer range.

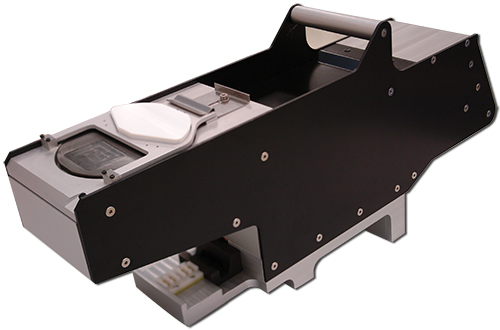

Tray Loaders

The auto tray loader (sequencer) is a vertical feeder storing up to 30 trays. Thanks to the large replenishment door, trays can be replenished during use, without halting production.

Automatic Tray Loader

- Intelligent feeder

- Handles up to 30 ‘vertically-held’ matrix trays

- Easily exchangeable with a tape or feeder trolley in less than a minute

- Rejected components are placed back in their original cell

- Trays can be replenished during production without halting the machine

Automatic SMT Tray Loader

Jedec trays or other matrix trays with a maximum size of 340mm x 190mm x 13mm are fed automatically to the pick up position. Occupying a single feeder zone, the storage capacity for devices ready to be presented to the placement head is second-to-none. Once the contents are depleted, or the feeder no longer required for production, it’s easy to slide the loader out and replace it with alternative trolleys or carts to complete the cycle.

The auto tray loader can be programmed offline to improve machine utilisation, or online once loaded into the feeder zone on the machine.

Machine Options

Nozzles

Europlacer uses Smart nozzles constructed from thermo plastics to significantly reduce replacement cost and prevent ESD on static sensitive devices.

Smart Nozzles

The majority of nozzles available in the market are of an expensive steel construction with vacuum pickup.

The Smart Nozzle concept is simple: it has a unique identity encoded onto the nozzle that verifies that the correct nozzle is being used. Smart nozzles can be quickly set anywhere in the tool banks, removing all possible errors due to an operator placing a nozzle in the wrong position.

Thanks to a very powerful internal vacuum system, Europlacer machines reduce operational costs by handling the majority of SMT devices with a small range of smart nozzles,

Where vacuum is not appropriate, and devices require special handling, Europlacer offers a range of adjustable gripper nozzles. And we can design special nozzles around customers’ specific applications for any odd form components.

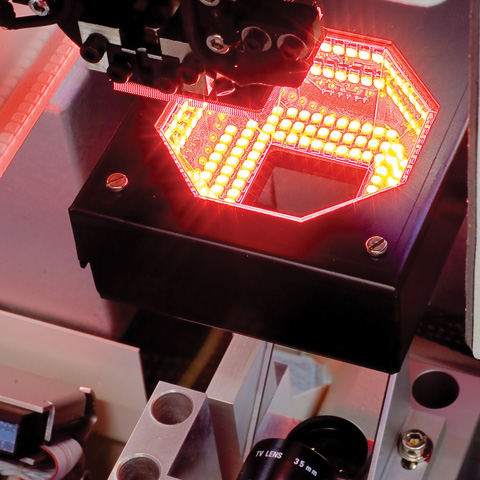

Fixed Camera

Europlacer is recognised as being at the forefront of vision capability, and has evolved its technology alongside some of the most challenging customer applications. Our software algorithms combine with our own vision and lighting systems to manage the most complicated of component packages.

Vision System

A powerful vision system is a key feature in any pick & place machine, and there are no short cuts. Europlacer developed its own vision algorithms to analyse QFPs back in the 1980s.

This high-resolution camera is used for inspection of ultra fine pitch components, µBGA, and flip chip devices. It’s also used for components larger than the 50mm x 50mm specification of the “on the fly” camera, to give accurate machine vision up to 99mm x 99mm.

It can acquire images in single field of view (SFOV) or multiple field of view (MFOV) modes. By locating it between the feeder zones on iineo, it does not reduce the maximum feeder count.

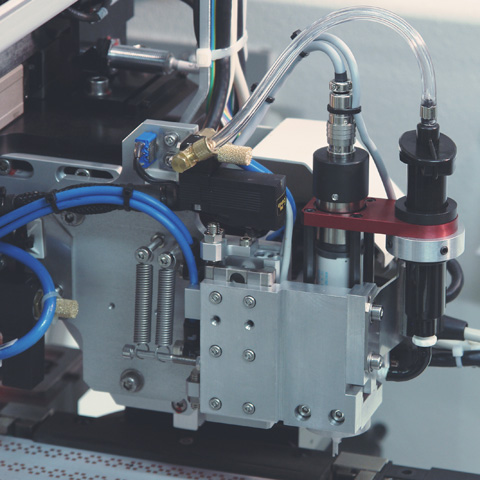

Glue/Paste Dispensing

There are two types of dispenser available to you, allowing the deposition of glue or solder paste within the placement machine, and crucially, without losing any feeder capacity or placement performance.

Adhesive / Solder Paste Dispenser

Mounted directly to the placement head and therefore utilising the positional accuracy and control, the dispenser provides consistent dots of glue or solder directly to the substrate prior to component placement.

Fully programmable, different dot sizes can be applied depending on package library parameters to increase the level of flexibility within the placement platform.

Adhesive dots are generally used to hold certain passive components onto the PCB during the wave soldering process.

With pin-in-paste technology, through-hole (PTH) component placement can follow the SMD component placement process, with both being reflowed together in the oven. Using our solder paste dispenser, plated-through component holes are filled before the insertion of the components. This eliminates the wave soldering process altogether to dramatically improve line throughput and efficiency.

Two dispensers are available :

- air / time system – providing an economic dispensing system (iico and iineo)

- archimedean screw – the ultimate in control and performance (iineo)

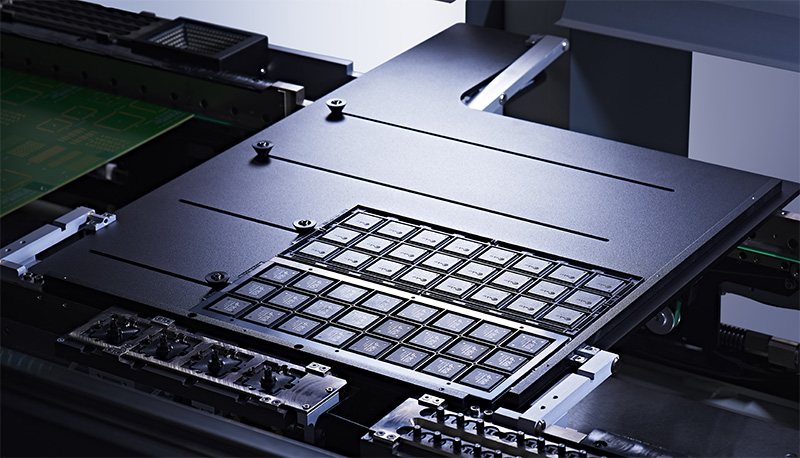

Internal Matrix Tray Holders

A variety of different matrix tray holders may be fitted as standard inside our machines, with no impact on standard PCB dimensions or tape feeder capacity.

- Intelligent feeder

- Up to 10 Jedec trays on iineo+ I

- Up to 3 Jedec trays on iineo+ II

- Up to 5 Jedec trays on atom 3

- Up to 4 Jedec trays on iico

- Up to 66 unique part numbers (more on demand)

- Easy to program through the machine graphical interface

- No reduction in machine feeder capacity or maximum PCB size

Capable of accepting standard Jedec trays the holders provide significant capacity for the presentation of QFPs, BGAs, connectors, heatsinks and any other non taped devices.

If you have a specific application, tray holders can be customised to fit your need.

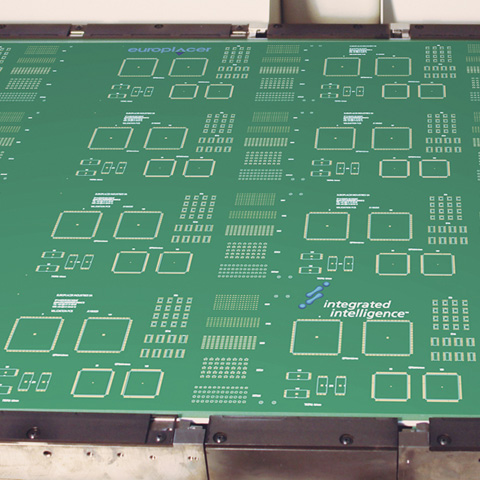

Long/Large PCB’s

Having the largest board capability in the industry provides users with a solution to applications such as LED panel and LED strip production. Now you can manufacture panels in one shot, without needing to move the PCB in steps within the machine. It reduces process risks within the production operation.

Large boards

If large boards are your thing, then iineo is for you!

The incredible flexibility of the iineo platform allows you to configure the internal conveyor within the the machine and produce any PCB up to 1610mm x 600mm in size, while still maintaining all the standard features that iineoprovides.

If your PCBs are less than 460mm wide, you still maintain the full 264 x 8mm feeder positions. Where PCBs greater than 460mm need to be accommodated, you still get an impressive 132 feeders positions.

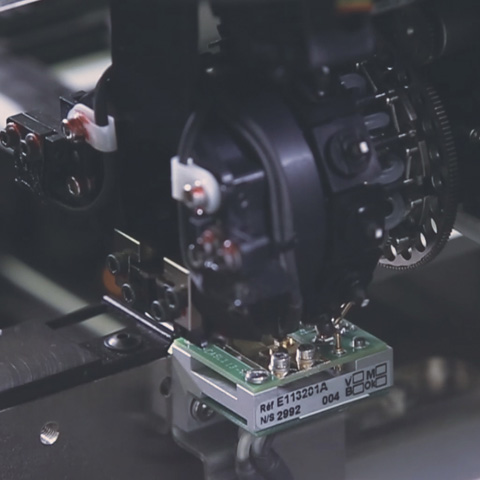

Electrical Test

Europlacer’s component tester is a critical option for customers working within high specification fields such as automotive, military, medical or avionics.

SMD Component Tester

Crucially, the tester can be independently calibrated against all international standards & institutes. It guarantees you and your customer the statutory performance required when working on demanding applications.

Some suppliers provide a ‘verification’ system to check component status. However these units are unlikely to be independently verifiable against international standards of compliance.

Europlacer’s electrical test head is mounted inside the machine structure, and does not compromise any platform resources, including the feeder count. The head comprises a measuring bridge consisting of four electrodes linked to a flexible circuit, on which the machine places the components to be measured.

The component tester can measure resistors, capacitors, diodes and inductors with voltages up to 40V. It can be programmed to test all components prior to placement, or the first and last components to verify correct feeder loading. Built into the platform structure, the component tester is an intrinsic element of Europlacer’s integrated intelligence system.

All test data is held at component level to provide control and, where necessary, trace-ability at individual circuit level to give confidence that you’ve completed the process within design and production limits.