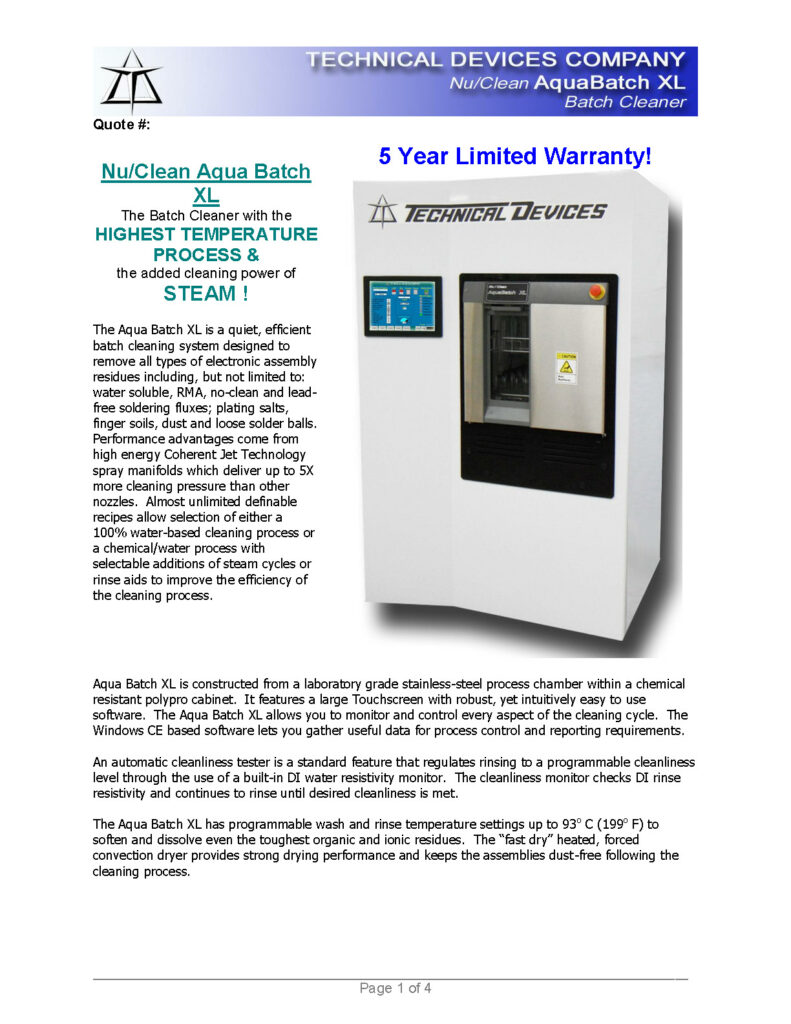

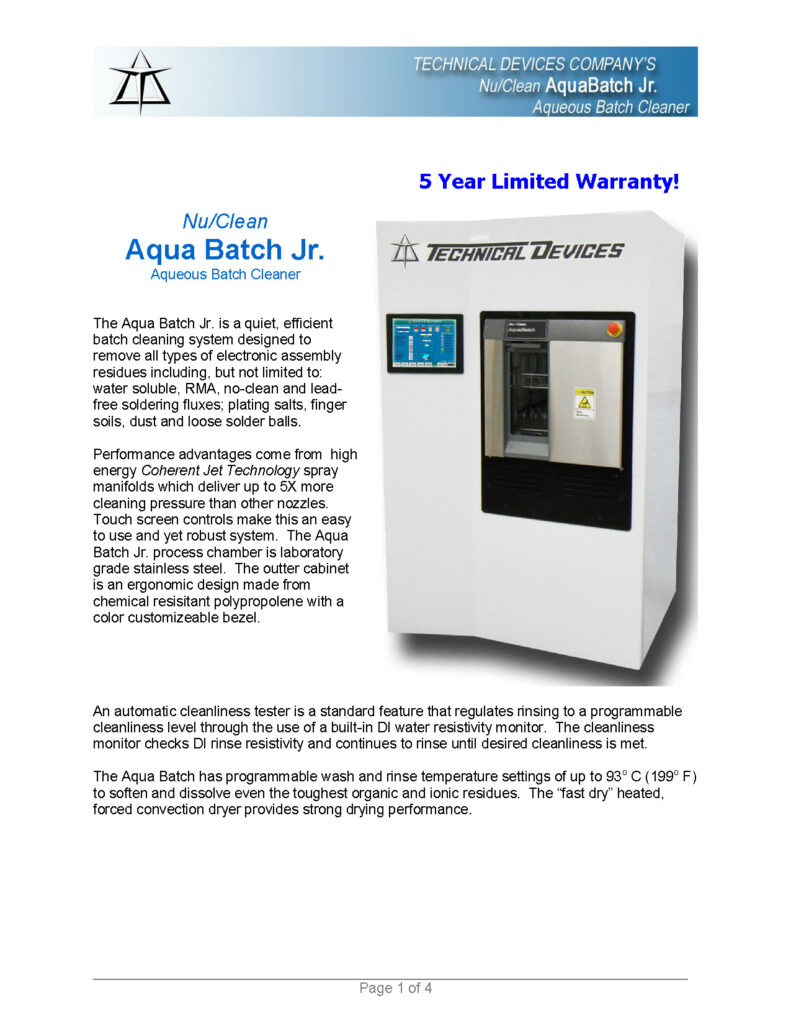

Forget the limitations of the past and experience a batch system that offers multiple cleaning technologies for capability previously unachieved in a compact footprint. In addition to aqueous and aqueous chemistry-based cleaning, the innovative Aqua Batch supports process temperature ranges from ambient to 200°F and adds the Power of STEAM! When selected, the onboard steam generator produces hot water vapor to penetrate and soften tough, baked-on flux and paste residue so the standard wash cycle can effectively complete the cleaning process. An intuitive user interface allows the operator to select the type and duration of wash, number of rinse cycles, and duration of the forced-air dry cycle.

AquaBatch XL

AquaBatch Jr.