TruView Fusion

The Truview™ Fusion X-ray Inspection System is the most versatile x-ray machine in the market today. Capable of inspecting samples up to 20″x20″ (or 20″x48″ in X mode), the TruView™ Fusion can be powered with x-ray sources from 80kV to 150kV. When powered with a transmissive x-ray source, the TruView™ Fusion can achieve magnifications up to 2,000X.

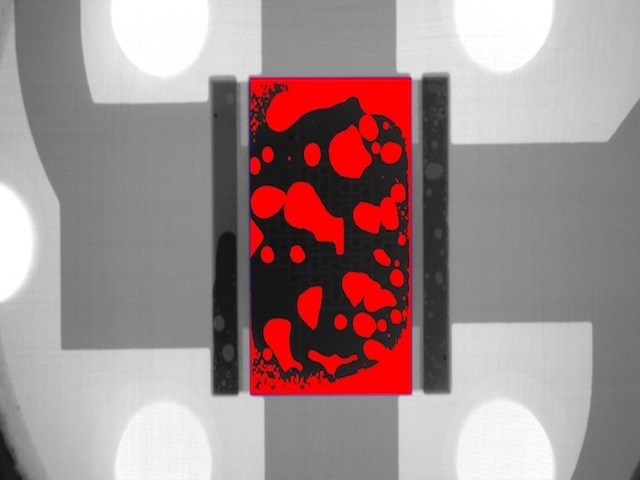

The other unique feature of the TruView™ Fusion is the fully automated defect detection capability. The TruView™ 10 Software Premium allows you to program a complete suite of tests in the TruView™ Fusion, which can be repeated on a batch of samples. With full pass/fail capabilities, this system can either assist or replace an experienced operator.

With a wide range of applications utilizing the TruView™ Fusion, it’s time for you to learn how this powerful machine can improve your bottom line.

X-ray Source Voltage: variable, up to 80kV, 90kV, 110kV, 130kV, or 150kV.

X-ray Camera: 3″x4″, 4″x6″, or 8″x8″ flat panel.

Sample Manipulation: Fully automated X, Y, Z, and x-ray sensor tilt. Sample and stage rotations also available.

System Dimensions (LxWxH): 48”x36”x65”.

Maximum Visible Sample Area: 20″x20″ or 20″x48″.

Magnification: variable, up to 2,000X.

Included Software: TruView 10 Standard.

Included Computer: PC with latest Windows OS, fully networkable.

Optional Upgrades: TruView 10 Premium, cart, sample rotation mechanism, stage tilt, joystick, laboratory bench. Inspection automation and custom path macros.

Warranty: 3-year warranty.

Safety: FDA compliant and CE certified. Cabinet fully shielded with multiple interlocks, keyed start switch, and emergency stop switch. Certified to operate worldwide.

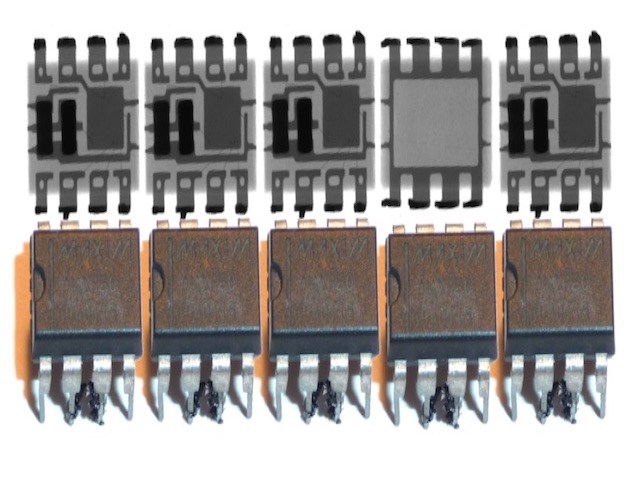

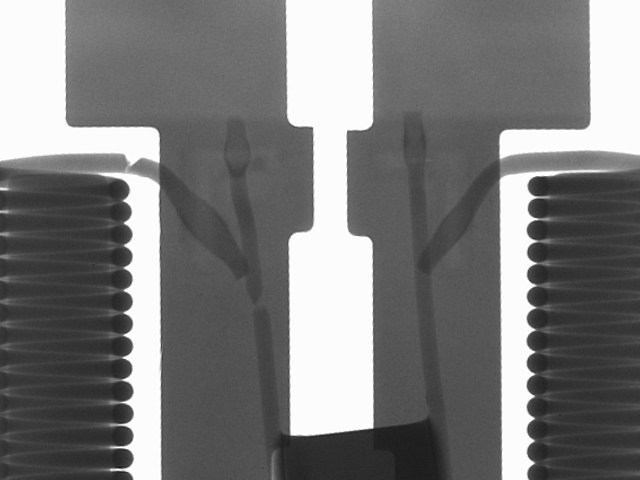

Applications

Reel to Reel

Automotive Relay

LED Panels

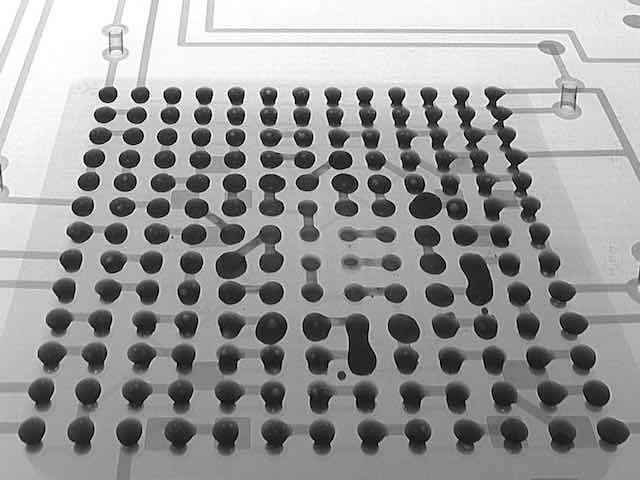

PCB Inspection