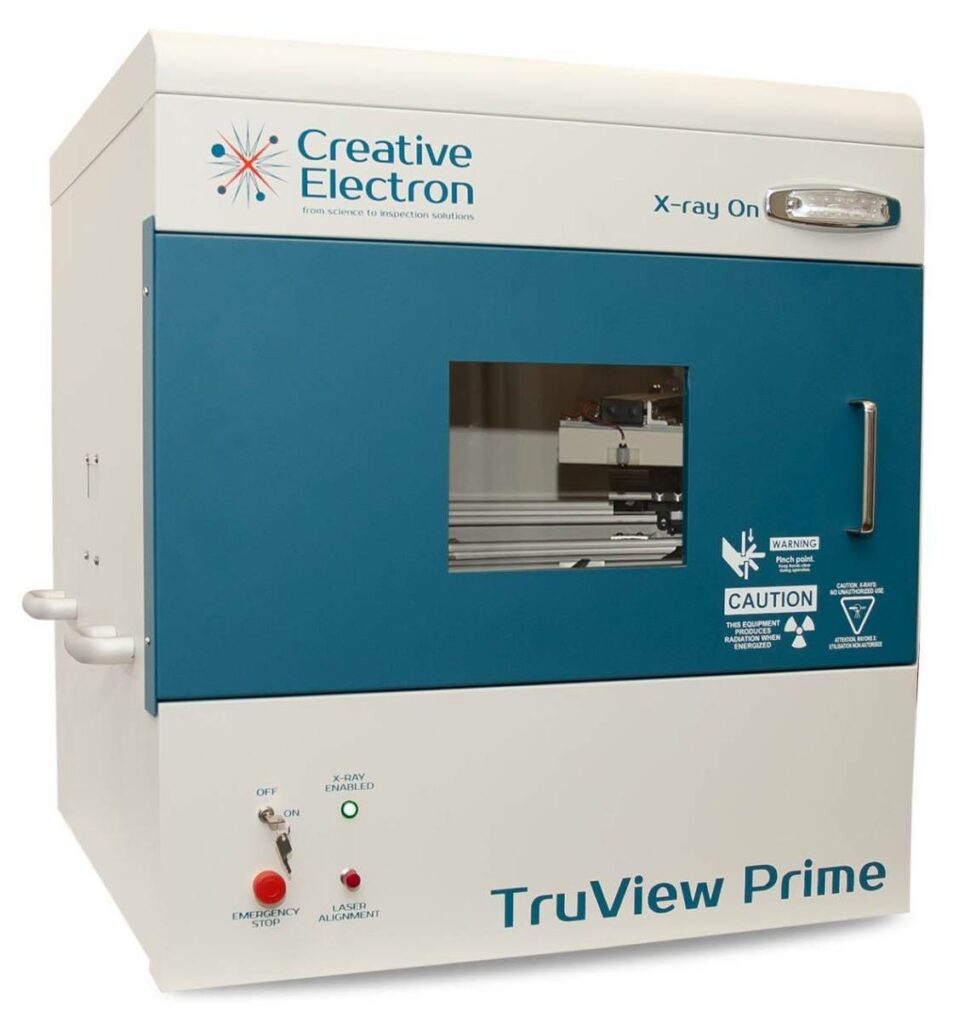

TruView Prime

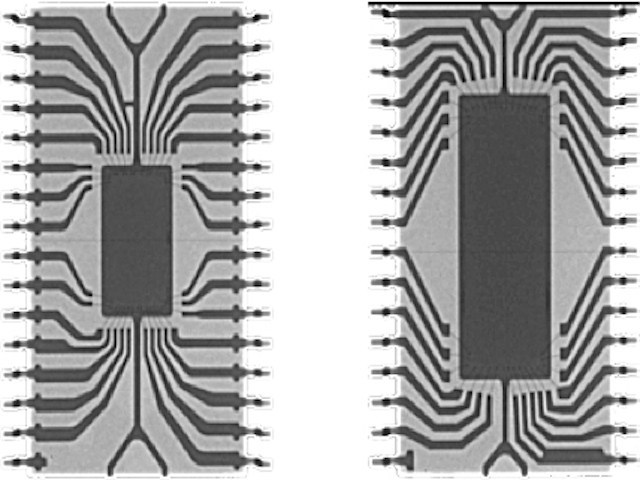

For several years technical teams had to make a decision: to buy a large x-ray inspection system for good image quality, or to buy a benchtop x-ray system for low image quality. The TruView™ Prime breaks this paradigm by offering outstanding image quality in a benchtop configuration. The TruView™ Prime can be configured as a generic x-ray inspection system, ideal for use in PCB inspection (BGA and QFN), or it can be configured in a high magnification mode (using a transmissive x-ray source), ideal for semiconductor failure analysis with geometric magnification to 1,000X. The TruView™ Prime was designed to be easy to use. Utilizing the principles of “plug-and-play”, the TruView™ Prime can be installed and ran with minimal training. The TruView™ Prime is a semi-automated x-ray inspection system when powered by the TruView™ 10 Premium,

X-ray Source Voltage: variable, up to 80kV, 90kV, 110kV, or 130kV.

X-ray Camera: 3″x4″, or 4″x6″ 14-bit flat panel.

Sample Manipulation: Motorized and controlled by keyboard. Automation available with TruView 10 Premium.

System Dimensions (LxWxH): 31”x31”x35” (without cart or reel-to-reel).

Maximum Visible Sample Area: 12″x12″.

Magnification: variable, up to 1,000X.

Included Software: TruView 10 Standard.

Included Computer: PC with latest Windows OS, fully networkable.

Optional Upgrades: TruView 10 Premium, cart, sample rotation mechanism, stage tilt, joystick, laboratory bench. Inspection automation and custom path macros.

Warranty: 3-year warranty.

Safety: FDA compliant and CE certified. Cabinet fully shielded with multiple interlocks, keyed start switch, and emergency stop switch. Certified to operate worldwide.

Applications

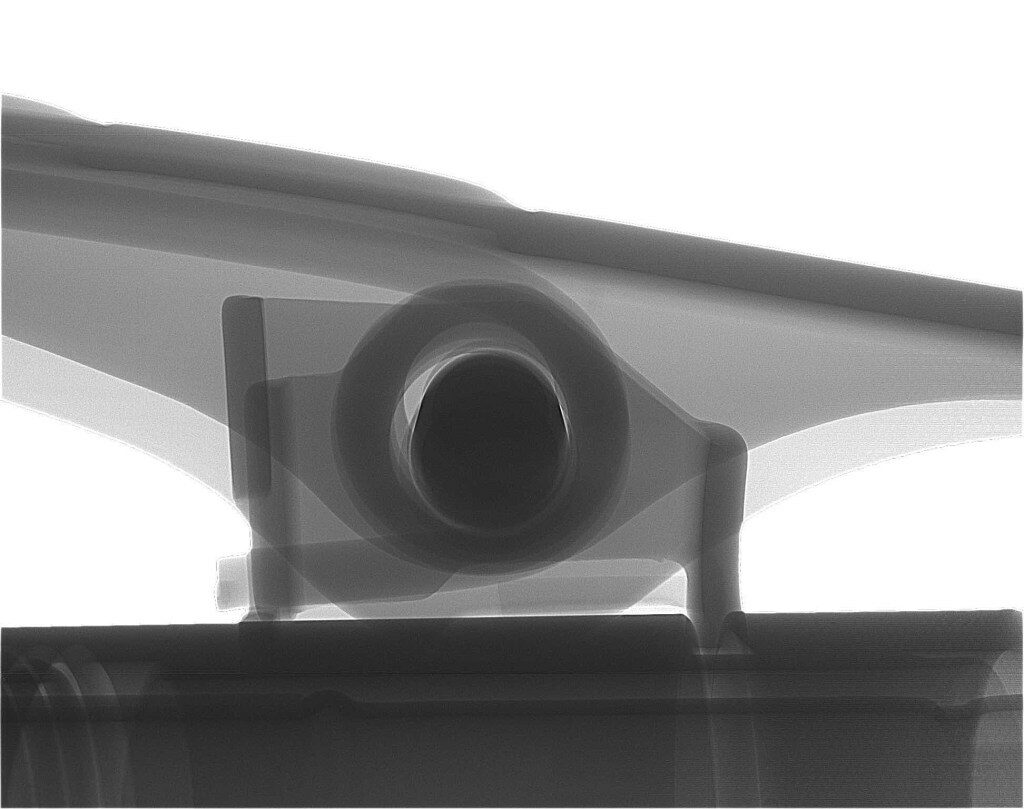

Aluminum Casting

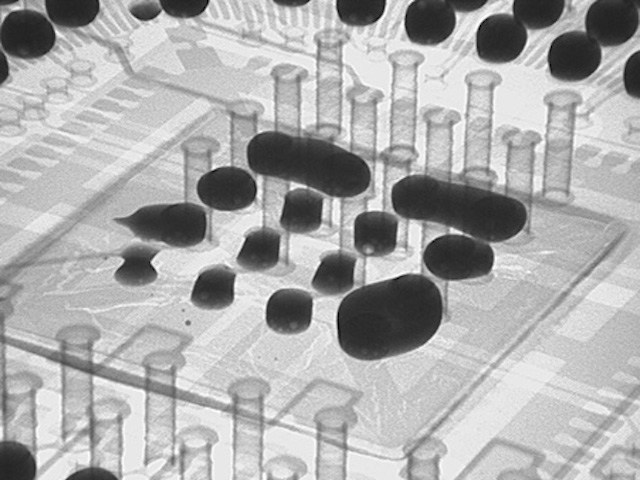

Automated BGA Inspection

Automotive Parts

Counterfeit Components