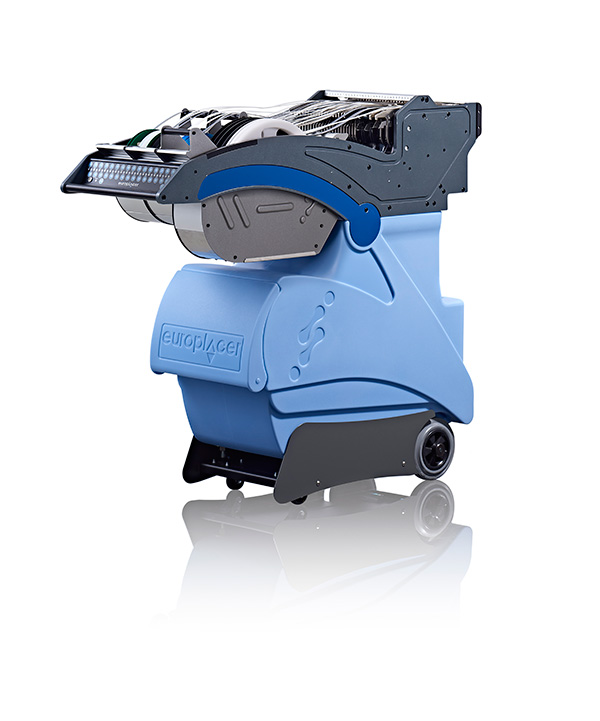

Now it’s possible to have a high speed AND flexible solution – with no compromise

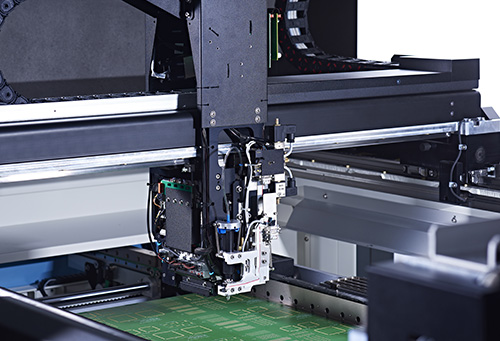

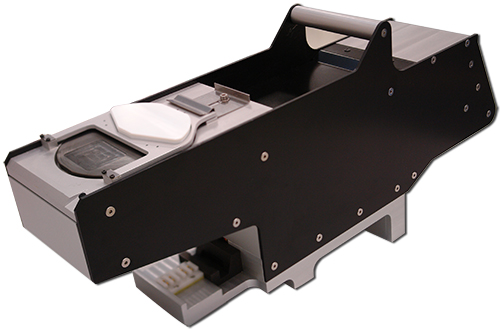

Atom 3

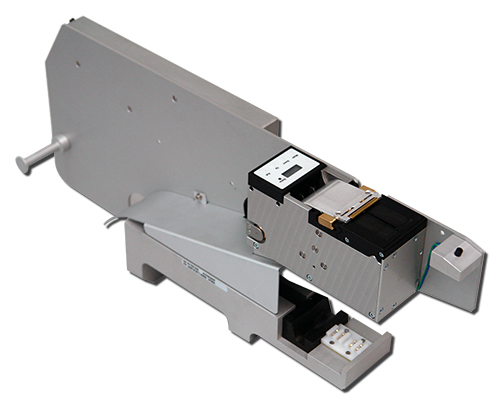

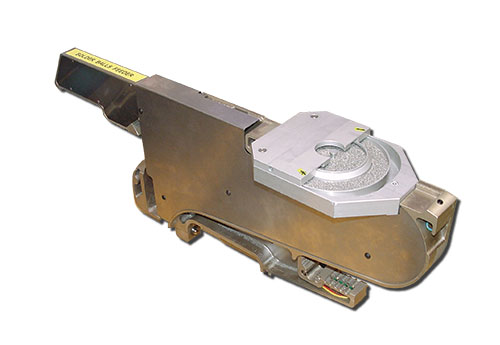

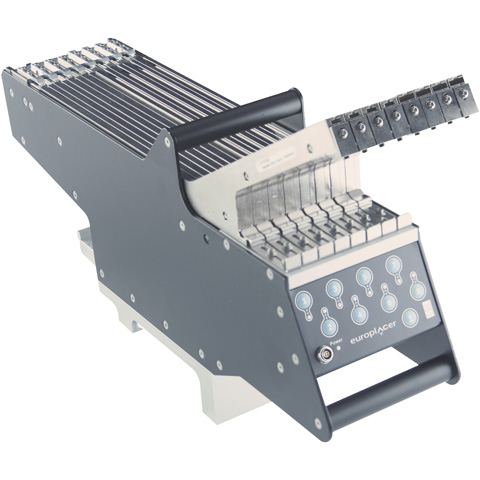

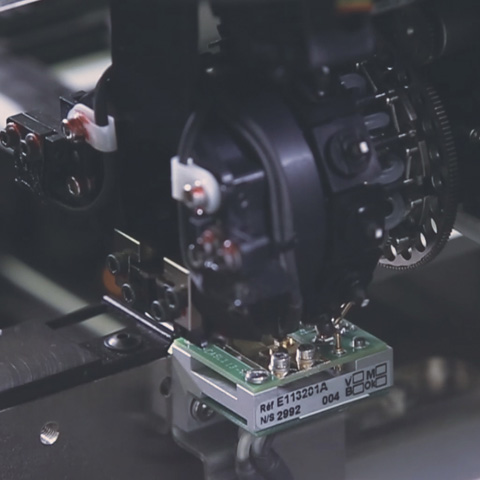

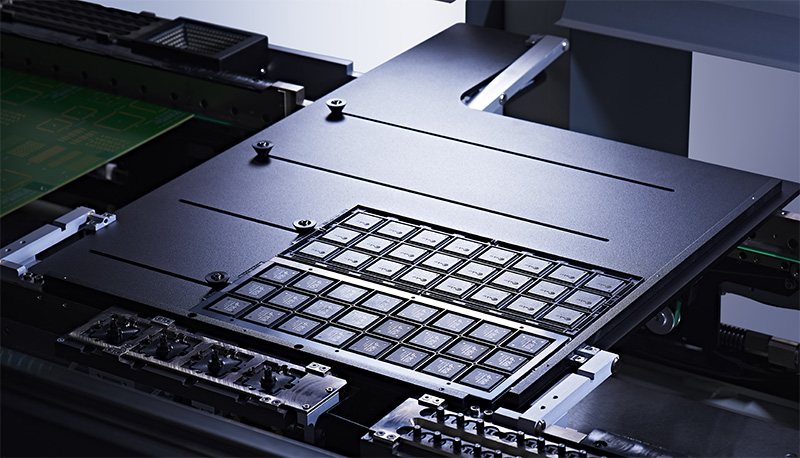

Atom 3 deploys a pair of the new high-speed Pulsar heads, each on an independent axis, and adds proven Tornado turret technology that makes iineo+ the industry’s most flexible placement machine. That Tornado head is on its own axis and is specified with eight nozzles. With those three heads working together, and placement optimised by our latest software, Atom 3 achieves rates up to 65,000 components per hour for devices from 01005 profile to 99mm². It is Europlacer’s most flexible machine ever.

Over five years in development, the Europlacer design team set out to engineer a new platform that combines very high placement speeds with our legendary placement flexibility and accuracy. They succeeded. The result is Atom.

Atom 3 uses 2 Pulsar Heads combined with our proven Tornado Head and will provide speed of up to 65,000cph while catering for the complete range of SMT devices up to 34mm in height, and can even handle through hole devices with its gripping nozzle capability.

Atom 3:

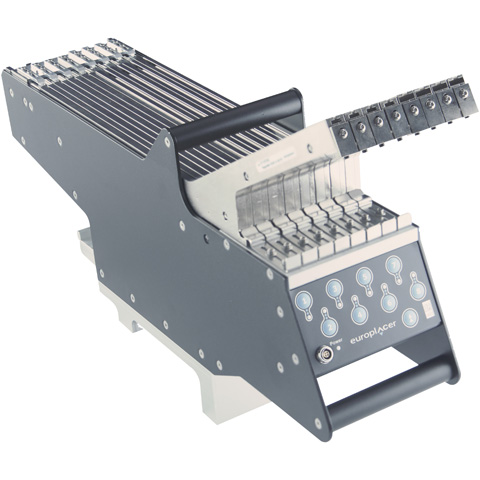

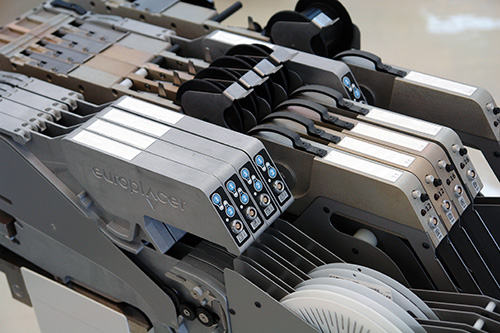

- 264 x 8mm feeders

- up to 5 internal Jedec trays

- 01005 to 99 x 99 mm components

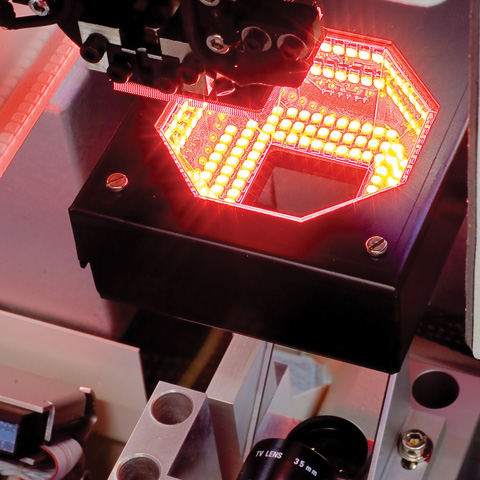

- 35 µm (QFPs), 50 µm (chips) @ 3 sigma

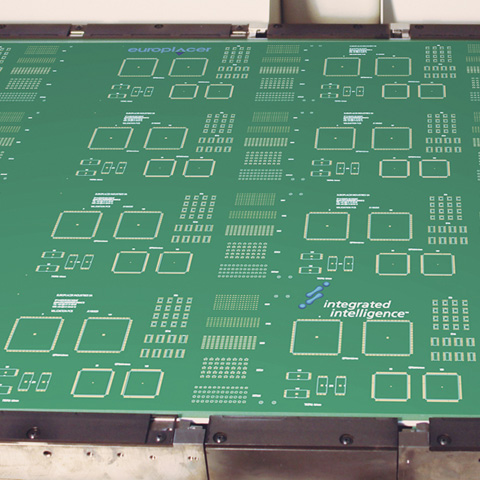

- PCB size up to 2059mm x 715mm

- Component weight & height – 300g & 34mm

- Component testing capability – with independently verifiable calibration (UKAS / NIST / PTB… etc.)

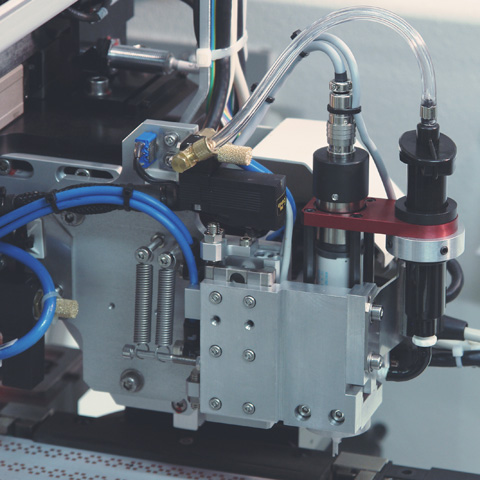

- Dispensing – Archimedes or air/time for glue or solder paste

- Every nozzle position can place all and any component types, for real line balancing and no limitations

- Odd form & smart nozzle banks

- Atom 3 65,000CPH Max

Click on the image below to learn more about the Atom 3